Using Delta T for Assessing Spray Conditions

The majority of boom spray operators will be well versed in assessing environmental conditions before spraying, and with using Delta T to assist with this. Delta T is one of the main indicators for assessing spray conditions. Although applicable all year round it is especially useful in summer when higher temperatures and low relative humidity limit spraying time.

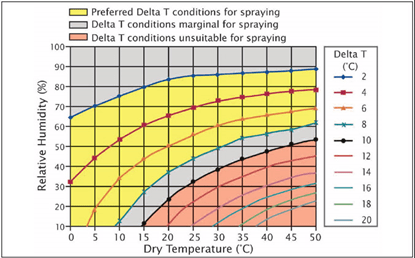

Delta T is calculated by subtracting the wet bulb temperature from the dry bulb temperature. The chart (Figure 1.) relates air temperature and relative humidity to values of Delta T. Delta T is used to indicate evaporation rate and droplet survival. When the value is too high the spray droplet will dry up before the herbicide gets a chance to move into the plant, resulting in reduced herbicide efficacy or delayed herbicide uptake. If the value is very low, then droplet survival will be very long and will slow the speed of herbicide uptake leading to increased potential for drift or washing off if rainfall occurs.

The ideal Delta T for spraying is between 2 & 8. However, over the last few years it has been shown that spraying for longer when the Delta T value rises to 10 or even 12+ can be successful. Visually looking at weeds is the best method for determining if spraying at higher Delta T values can be done. If weeds are small, look fresh and are actively growing, then they will take up herbicides well. Conversely, stressed weeds (e.g. moisture or temperature stress) are not going to take up herbicides as well and should be sprayed under better/ideal conditions; avoid spraying in temperatures above 28 degrees and spray when wind is ideally between 3 and 15 km/h.

When spraying into more marginal environmental conditions having the correct boom setup is important. Under higher Delta T values using coarse to very coarse droplets, higher water rates >80L/ha, using a good adjuvant such as Smart Penetrator or Smart 700 Spray and slowing down if conditions become dusty will all help the spray job.

If you’d like any more information please get in touch with one of our agronomists here.

Figure 1: Delta T – Optimal Conditions for Spraying

As of October 1st 2019, new label instructions came into effect for 2,4-D labels – this affects about 220 products. For more information on these changes please click here for 2,4-D new label details or here for a more detailed look at spray drift management from the APVMA.

The Smart Agro